Telepathology for Everybody: Part 1

The story of the OpenFlexure 3D-printable microscope

Helen Bristow | | 5 min read | Interview

Joe Knapper testing OpenFlexure devices on site at the University Teaching Hospital of Butare, Rwanda

Credit: Joe Knapper (CC-BY)

With the potential of making telepathology a reality wherever it is needed, a group at the University of Glasgow in the UK have developed an open source, 3D-printed digital microscope that can be constructed in the lab for around $300. Users simply download the free 3D design, print the body, order a few low-cost parts, put it all together, and attach it to a laptop or monitor.

Here, Joe Knapper, one of the developers of the OpenFlexure device, shared the story of its development, some of the world health issues it could help address, and where it’s already proving its low-cost worth.

Read part two of this article to hear from the pathologists who are helping to develop applications for OpenFlexure.

How did the project come about?

The device was invented by Richard Bowman, who specializes in optics. He had access to a 3D printer and started trying to create a small device that would hold a camera and a slide in place. It just got more sophisticated from there – he secured some funding and started adding gearing and automation.

The problem he wanted to address is that of access to microscopes and slide scanners in low-resource areas of the world. A typical digital pathology workflow is simply not accessible to many hospitals in the world, where funding, computer power, and reliable wi-fi are in short supply, and where service contracts are prohibitively expensive. The OpenFlexure device can be used as a small slide scanner for telepathology – for teaching, research, and hopefully for diagnosis – and can be constructed, used, and maintained by pathologists.

An assembled OpenFlexure microscope

Credit: openflexure.org (CC-BY)

What is your involvement in the OpenFlexure project?

As a physics and engineering graduate, I first worked on the OpenFlexure project for my PhD at the University of Bath. My focus is on global health applications for the microscope, particularly in the diagnosis of malaria.

Why is the OpenFlexure digital microscope so accessible?

The body and mechanics can be printed on the most basic 3D printers available, and the other parts are low-cost and all available online from a few different suppliers. The whole thing typically costs less than $300 in parts. We’ve worked hard on the instructions to allow a non-specialist to construct and maintain the device in house.

Printing can be done in a few hours, or overnight. Construction takes me around two hours, but may be a little more for the first-time user.

The design includes a Raspberry Pi camera and three motors for automated microscopy. The only other thing you need is a monitor to view the images on. I like to use a laptop for the controls, but it’s not essential. The device can be powered from a portable charger if there is no power source available or if it is being operated in the field.

How does the device perform in terms of image quality?

The microscope can now automatically scan a stained sample, skipping background areas to only image the sample without user input. It then tiles the image automatically, displaying it to the monitor. In terms of resolution and contrast, we can resolve plasmodium parasites, and, though it is slower than a proprietary slide scanner, the low cost makes it feasible to set up several in parallel. Our next big challenge is turning it from a piece of lab equipment to a healthcare slide scanner. A couple of single-site studies have assessed the performance as suitable for identifying dysplasia, tuberculosis, and rheumatic heart disease (1, 2).

Tell us about the recent field testing you have been doing and what you learnt from it…

We have taken the device to Tanzania and, more recently, to Rwanda. We wanted to see how practical it was to build/set up the devices on site and train the pathologists to use them. We found that some of the microscope parts that we can order easily online are not available in some countries, and had to be shipped from neighboring countries.

We also wanted to see how the device would fit into their workflow and, importantly, how the pathologists would perceive it. It’s low cost, made of plastic, and has the option to be printed in bright colors; but it’s also an important piece of laboratory equipment. We noticed that the appearance of the kit could sometimes be disconcerting for the medical teams.

But, when we used it to look at pathology samples, the reception was really positive. We were asked if it would be suitable for malaria testing, which is one of the areas in which we could receive research funding.

Some users were interested in the device for sample preparation. It gave them the opportunity to have a quick check of the sample quality on a screen before booking time on the proprietary microscope.

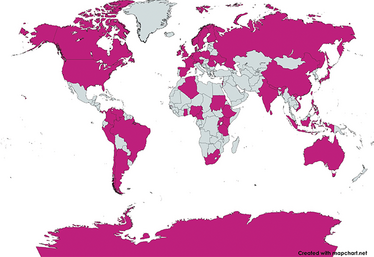

Countries (in pink) where OpenFlexure devices have been constructed or used.

Credit: openflexure.org (CC-BY)

What advice would you give to other young innovators or inventors in terms of developing their ideas?

Talk to your target end users as early as possible. That can be an uncomfortable process and you might be told there’s no need for your idea in healthcare or that you don’t understand the challenges that people in Africa are facing, for example. But it’s much better to hear that uncomfortable feedback early on rather than spending months trying to solve a problem only to be told, “We don’t struggle with that.”

Our online forum (https://openflexure.discourse.group) has been invaluable for accessing feedback and hearing how the device has performed in different applications. We’ve learned that OpenFlexure devices have been built in over 50 countries and used for purposes as diverse as teaching, soil health monitoring, and plant microscopy. We’ve also had someone share that they’ve used our microscope in an area of the Ukraine war for epidemiology, and we know it has been used in the Antarctic to monitor ice quality. We even heard that one couple built one on a date!

- D G Rosen et al. “Utility of a low-cost 3-D printed microscope for evaluating esophageal biopsies.” Ann 3D Print Med, 13 (2024). PMID: 38405263.

- M K E Cabello and J E De Guzman. “Utilization of accessible resources in the fabrication of an affordable, portable, high-resolution, 3D printed, digital microscope for Philippine diagnostic applications.” PLOS Glob Public Health, 3, 11 (2023). PMID: 37988332.

Combining my dual backgrounds in science and communications to bring you compelling content in your speciality.